![]()

Table of Contents

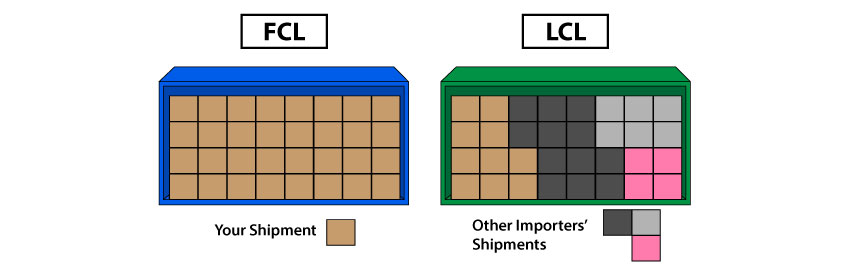

FCL vs LCL

Shipping is tough, especially in the current climate.

There are many important decisions to make when it comes to shipping ocean freight.

Some of these decisions can make the difference between success and failure. In ocean freight shipping, one of the most important decisions is how to choose between full container load (FCL) versus less-than-container load (LCL).

For new shippers looking into sea freight, it’s critical to know the difference between full container load vs LCL. So let’s look at the decision process and some of the issues that come into play along the way.

To start, we’ll cover the definition of ocean container shipping. Next, we’ll look at the difference between FCL vs LCL.

We’ll also run through how to make the decision, including the cost issues that are part of the equation.

What Is Ocean Freight Container Shipping?

Ocean container shipping is the process of loading goods into a steel box called a container. The container gets transported onto a large cargo vessel along with many others. Then, the ship transports the cargo to other continents by sea.

Ocean freight shipping has a long and successful track record. However, there is risk involved, most of it having to do with mother nature and the sea.

One of the most common risks relates to shipping incidents like fire at sea or groundings. For example, the cargo ship Ever Given blocked the Suez Canal for a week in 2021, which caused a major backup of over 50 ships.

The grounding led to a ripple effect of major backlogs when busy ports didn’t have enough open berths for late arrivals. Shipping backlogs can cause significant economic and global supply chain slowdowns.

What is the Difference Between FCL vs LCL?

The difference between FCL and LCL is that a buyer shares the container space with other shippers for an LCL shipment, versus paying for the entire container space with an FCL shipment.

Freight carriers use many different types of containers. The most common type used in manufactured goods shipping is either a 20 or 40-foot dry container.

The main decision for anyone looking to import or export products is whether to go with FCL or LCL.

The advantage of going with FCL depends on the size of your order. Using a full container means that you don’t share the space with another shipper.

You may also get preferential scheduling with an FCL booking which can be a huge time advantage.

Conversely, Many companies ship LCL for cost savings. Shipping less than a container load is great for smaller loads that only fill part of the container.

Sharing space also helps keep costs down, but there can be delays due to scheduling issues. But the cost savings can be a major advantage compared to FCL and air freight shipping.

It’s also important to know some of the terminologies involved in ocean freight. Shipping container sizes vary. While there are many different container types, 20-and 40-foot containers are the most common options. The industry standard for measuring a container’s capacity is in cubic meters. “CBM” is the standard abbreviation for this unit.

Learn more about container dimensions.

How do you Choose Between FCL and LCL?

Deciding between shipping FCL vs LCL can be a bit complicated. This is because there are so many different factors to consider. It is possible to sum them up, though, so we’ll start here.

The advantages of FCL are the speed of shipping and the security of your goods. And the flexibility of having more control of how and when you can load goods into the container. It’s generally more cost-effective for loads with a volume of over 10 CBM.

One of the main disadvantages of FCL is that you may have higher costs.

LCL offers flexibility at cheaper rates, and it’s ideal for loads in the 1-10 CBM range. In general, LCL shipping tends to be slower because of the need to merge goods going to the same destination.

Security can be a factor with LCL shipments. Containers loaded at different times and places can increase the possible theft or damage of goods.

Keep in mind that due to port congestion and delays your overall transit time for FCL and LCL may be impacted.

Which is More Cost-Effective LCL or FCL?

This is something of a loaded question. There are different factors and tradeoffs to consider in your decision. Some shipping scenarios favor FCL cost-wise, while others make LCL the best option.

It is possible to make some solid generalizations, though. If time is on your side and your shipment is less than 10 CBM, LCL is the way to go.

For larger, time-sensitive loads over 10 CBM where the security of goods is important, then FCL may be a better choice.

These are very general conditions, and that’s where an experienced freight forwarder like BGI can help you make the right choice.

It’s also important to partner with a company that understands the current industry conditions and how to come up with solutions. They must be able to deliver the goods, both literally and figuratively, so factor that into the decision process as well.

To find out more about other ways we can help, check out the broad range of international freight services and 3PL logistics services on our website.

Based in Signal Hill, California, we work with clients globally.

Experience the Difference…